See how a global electronics manufacturer leveraged Micraft MES with AI-driven analytics to improve OEE, reduce scrap, and optimize predictive maintenance across multiple SMT and assembly lines.

By deploying AI-powered predictive insights, the client improved yield, reduced machine stoppages, and achieved near real-time decision-making on the shop floor.

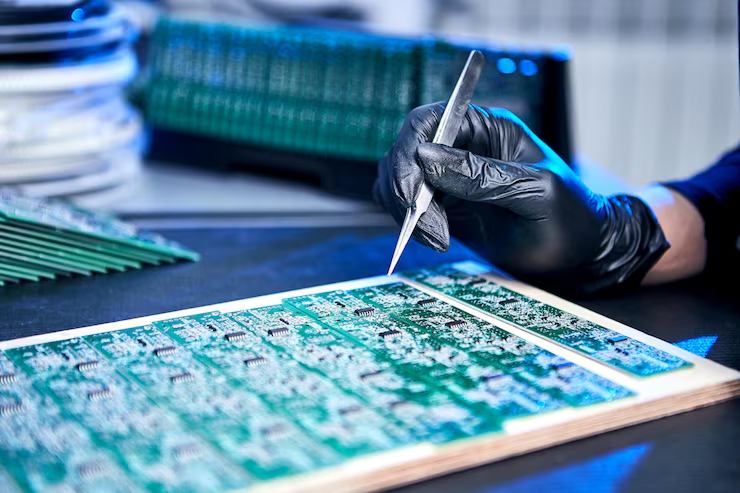

The client struggled with fluctuating yields, unplanned stoppages on SMT lines, and high scrap rates due to soldering and component placement errors. Lack of predictive maintenance and limited process visibility hampered efficiency.

Micraft MES with AI-driven analytics was deployed to track real-time OEE, apply predictive maintenance, and reduce process variation. Machine learning models identified early warning signals, preventing downtime and scrap.

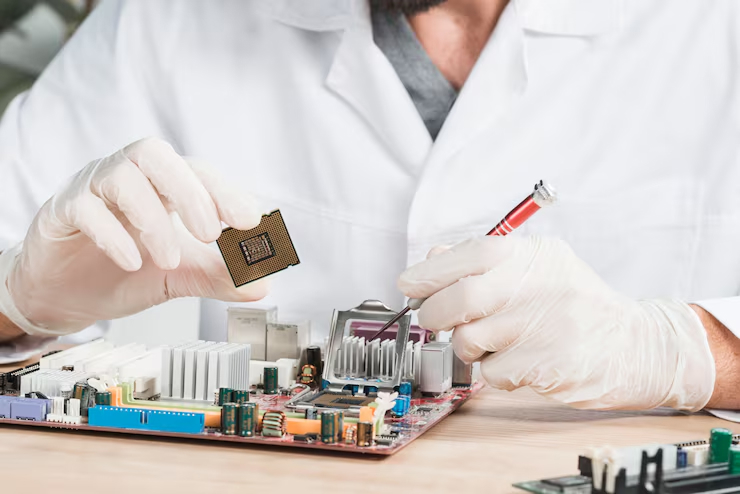

The MES was integrated with SMT line machines, AOI systems, and ERP. AI models were trained on historical failure and scrap data, then rolled out in a phased manner across three plants. Operators and engineers received AI-powered decision support via MES terminals.

Predictive alerts, yield trends, and quality deviations were displayed in real-time dashboards, enabling continuous improvement and faster corrective actions.

MES embedded with ML models for predictive maintenance & yield optimization.

Engineers trained to interpret AI insights and optimize parameters.

Direct machine data capture from SMT, AOI & ICT equipment.

Live dashboards with predictive KPIs for OEE, scrap, and defects.

The deployment of AI-powered MES led to significant gains in efficiency, yield, and predictive maintenance capabilities.

Micraft MES with AI delivered payback in under 8 months through reduced scrap, lower maintenance costs, and higher throughput.

Testimonial: “AI-powered MES gave us predictive insights to act before issues occurred. We’ve reduced scrap, improved yield, and made our lines far more reliable.”