Discover how a leading automotive parts manufacturer used Micraft MES to optimize production, reduce downtime, and improve traceability across multiple plants.

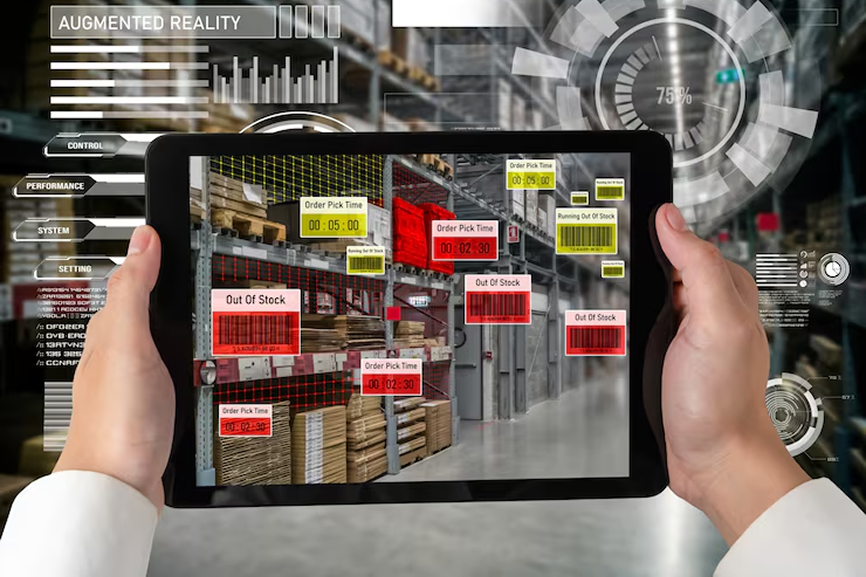

Micraft MES transformed production by bringing real-time visibility and actionable insights across four manufacturing facilities.

Frequent unplanned downtime and lack of real-time production visibility across multiple plants created operational inefficiencies, delays, and rising maintenance costs. The client needed a solution that could provide live production data, reduce downtime, and improve collaboration across facilities.

Micraft MES was deployed to monitor machines in real time, track downtime events, and provide operators with digital work instructions. Automated alerts ensured faster issue resolution and improved communication between production teams.

The MES was seamlessly integrated with the client’s existing ERP and PLCs. Operator training was conducted in phases, and the system was rolled out across 4 facilities to ensure minimal disruption during deployment.

Real-time synchronization allowed accurate production tracking, while role-based access improved data security. Automated reports reduced manual effort and helped managers take quicker decisions. A dedicated support team ensured smooth adoption and continuous improvement throughout the rollout.

MES integrated with ERP & PLCs for smooth data flow and centralized monitoring.

Step-by-step training sessions reduced learning curve and improved adoption.

Deployed across 4 facilities in phases, ensuring minimal disruption to operations.

Live dashboards tracked rollout performance and provided quick feedback loops.

The client achieved a 30% reduction in downtime, improved traceability, and actionable analytics that enabled continuous improvement. The system also ensured faster responses to production issues, reducing delays and scrap rates.

Micraft MES delivered payback within 9 months through reduced scrap, higher throughput, and lower maintenance costs. The client experienced tangible financial benefits with improved operational excellence.

Testimonial: “Micraft MES gave us the visibility and control we needed to drive operational excellence across our plants.”